A Comprehensive Guide to Understanding Litho Printing Strategies

The globe of litho printing, a method originating from the late 18th century, is a remarkable blend of history, advancement, art and scientific research. Keep with us as we journey right into the exciting realm of litho printing.

The Historic Development of Litho Printing

The historic trajectory of litho printing, a critical innovation in the world of communication, is a captivating tale of human resourcefulness. The process advanced with the introduction of the rotating press, which considerably boosted efficiency. Each phase of litho printing's advancement showcases humanity's relentless quest of performance and quality in aesthetic interaction.

Translating the Scientific Research Behind Litho Printing Inks

Progressing in the exploration of litho printing strategies, the focus currently moves to the scientific research behind litho printing inks. The structure of these inks, their drying out process, and shade mixing strategies create the backbone of this complex art kind. Understanding these components is vital to mastering the craft and achieving the wanted print results.

Make-up of Litho Inks

In lithographic printing, the fundamental role of litho inks can not be overemphasized. The composition of litho inks varies depending on its function, however generally, they contain two major components - pigments and lorries. Pigments, the color-providing components, are carefully ground fragments put on hold in the lorry, a fluid that lugs the pigment onto the printing surface. The car is an intricate mix of solvents, resins, and oils, which affect the ink's drying time, attachment, and gloss. Additionally, numerous ingredients are present to enhance particular residential properties like circulation, drying out, and resistance to environmental effects. Each element plays an important component in the last print's top quality, making the precise formula of litho inks a detailed scientific research.

Ink Drying Process

From the make-up of litho inks, attention transforms to the remarkable procedure of ink drying out. 2 primary techniques are used in litho printing: oxidative drying and absorption. Absorption, on the various other hand, involves the ink leaking into the paper fibers, which is a much faster process however can lead to less vivid colors.

Color Mixing Methods

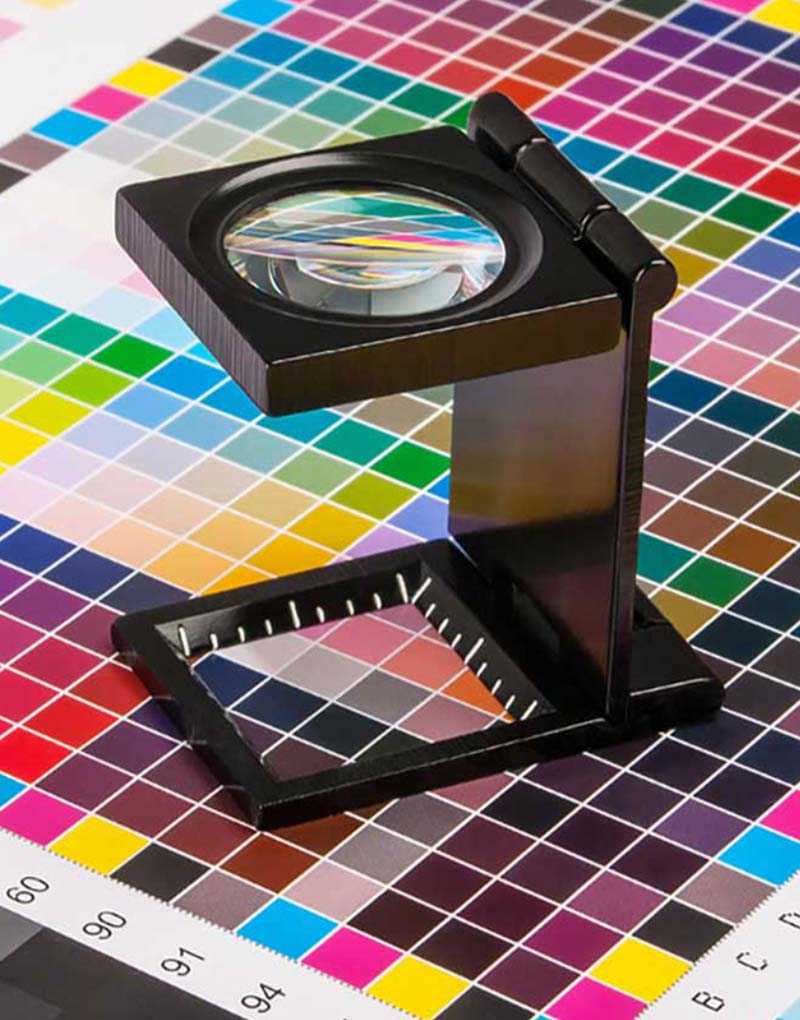

While the drying out process plays a vital function in litho printing, the scientific research of color blending methods holds equivalent value. The scientific research behind litho printing inks also takes into account the openness of the ink, which impacts exactly how shades overlay and mix.

The Art and Design Aspects in Litho Printing

Litho printing takes a breath life right into art and style through its unique elements. The process entails producing an image on a lithographic sedimentary rock plate or steel plate with a smooth surface area. The photo is after that printed onto a medium, generally paper, by transferring the ink from the plate. What collections litho publishing apart is its ability to replicate detailed layouts with high integrity, making the outcome virtually similar to the original artwork. This is attained via using various line strategies such as stippling, hatching, and cross-hatching, which permit a variety of tonal impacts. Additionally, litho printing fits a selection of shades, enabling artists to develop vibrant and dynamic prints. This mix of visit this page precision and flexibility makes litho printing a preferred choice for lots of artists and designers.

Modern Applications of Litho Printing Methods

Litho printing strategies have discovered considerable use in the modern business sector. Its impact and relevance remain to expand with the arrival of new innovations and innovations in the area. This area will certainly check out these contemporary applications and the transformative duty they play in the printing sector.

Commercial Litho Printing Uses

In today's electronic age, one could question regarding the importance of typical printing methods. Litho printing remains an essential part of the industrial market. High-volume printing jobs, such as the production of books, newspapers, and packaging, depend on litho printing for its ability to supply remarkable photo top quality important source and cost efficiency. The process, which involves moving a tattooed picture from a plate onto a rubber blanket and after that to the printing surface area, supplies unmatched uniformity. This makes it optimal for work requiring a huge print run. Litho printing likewise offers a wide color spectrum, above that of digital printing. This makes it the best option for tasks that require lively, top notch shade recreation.

Advancements in Litho Printing

Pressing the boundaries of conventional techniques, contemporary advancements have actually fueled a host of innovations in litho printing. One popular advancement is electronic litho printing, which incorporates the merits of electronic innovation with litho's top quality output. These technologies underscore the enduring relevance of litho printing in the modern globe.

Checking out the Refine of Litho Printing: Detailed

Difficulties and Solutions in Contemporary Litho Printing

In spite of the accuracy and practice that litho printing happily supports, it is not without its set of modern challenges. Digital litho printing allows for cost-efficient short runs and easy customization, addressing the issue of variable data. Thus, while there are difficulties, the litho printing sector is proactively adjusting to meet them head-on, ensuring its significance in the future.

Conclusion

In conclusion, litho printing, with its abundant background and clinical details, holds a substantial place in the print sector. The future of litho printing pivots on its ability to adapt to these changing demands, affirming its long-lasting worth in an advancing market.